Streamlining EPR Reporting & Plastic Tax Calculations with the Sustainability Thread

Extended producer responsibility (EPR) regulations fundamentally reshape how businesses manage packaging and plastic waste. From plastic packaging taxes to mandatory recycling quotas, companies are now required to collect, track, and report granular data on their packaging materials, waste generation, and recycling efforts.

However, manual data collection and fragmented reporting systems make compliance complex and error-prone. This is where the sustainability thread emerges as a transformative solution. By integrating digital systems, leveraging existing data, and enabling seamless sharing through connected data models, organizations can ensure accurate, efficient, and automated EPR reporting.

Our white paper, The Sustainability Thread, explores this concept and the synergy between sustainability and product lifecycle management (PLM).

This article illustrates how organizations can use the digital thread for sustainability data to streamline EPR data collection, transformation, tax calculations, and compliance reporting while reducing costs and regulatory risks. It provides executable actions every organization can take on its journey to the sustainability thread.

A Brief History of Extended Producer Responsibility (EPR)

EPR began taking shape in the 1970s and 1980s due to growing concerns over landfill waste and pollution. European governments led early experiments with producer responsibility policies targeting packaging and electronics.

The modern EPR framework emerged in the early 1990s, championed by Swedish economist Thomas Lindhqvist. Germany’s 1991 Packaging Ordinance introduced the Gruener Punkt (Green Dot) system, requiring producers to take responsibility for packaging waste. The OECD formally adopted EPR as a sustainability strategy, and the EU followed with recycling targets in 1996.

Global adoption expanded rapidly: the EU’s waste from electrical and electronic equipment (WEEE) directive followed in 2002, Japan and South Korea’s regulations in the 2010s, and recent legislation in California, India, and Canada. Although efforts are underway to harmonize global standards, such as the UN’s Intergovernmental Negotiating Committee (INC), each jurisdiction has its rules, reporting requirements, and methods to determine the resulting tax liabilities that companies must navigate. “The era of plastic regulation and reporting is upon us.”[1]

Understanding the Regulatory Focus

EPR regulations are designed to hold producers accountable for the entire lifecycle of their products, including collection, recycling, and disposal. These laws shift financial responsibility from municipalities to producers and incentivize sustainable packaging through eco-modulated fees.

Packaging is a central focus due to its short use phase and municipal disposal. Regulations typically consist of three components:

| Component | Examples |

| 1. Mandatory reporting | Oregon: Plastic Pollution and Recycling Modernization Act: Annual Report by Packaging Producers |

| 2. Commitment to reduction targets | India: Plastic Waste Management Rules: Producers/Importers/Brand Owners (PIBOs) must meet year-by-year targets for collecting and processing plastic packaging. |

| 3. Targeted taxation | UK: Plastic Packaging Tax: £200/tonne for plastic packaging with <30% recycled content. |

Some jurisdictions offer exemptions for biodegradable plastics, medical packaging, or high-recycled-content materials.

The Data Challenge: Prioritizing Collection for Compliance

One of the biggest hurdles in implementing the sustainability thread is sourcing detailed material data, particularly from suppliers. Key questions often can’t be answered using internal systems alone:

- What materials are used?

- Are they virgin or recycled?

- What is the composition breakdown?

Reporting requirements dictate the specific data that must be collected, often summarized by material type, weight, and geography. Given the complexity of regulations, companies need a prioritized data strategy based on product and packaging types, target jurisdictions, suppliers, and customer relationships. This strategy forms the backbone for implementing a focused and scalable sustainability thread.

Building the Data Model Foundation

A streamlined reporting process begins with a transparent, cross-system data model. The core entities include:

- Packaging Composition: Bill of Materials (BOM) for packaging elements

- Sold Product: Typically identified via SKU

- Sales Document: Captures quantity, timeframe, region, and customer data

The packaging BOM establishes the connection between each element, corresponding to its material types and relevant attributes. The specific reporting and regulatory requirements determine these attributes. Spain, for example, requires data on packaging separability. The report has to answer the question of who and when packaging elements are separated. On the other hand, the packaging report for the UK distinguishes between chemically and mechanically recycled plastic. Establishing this foundational data model is essential for accurate, scalable compliance.

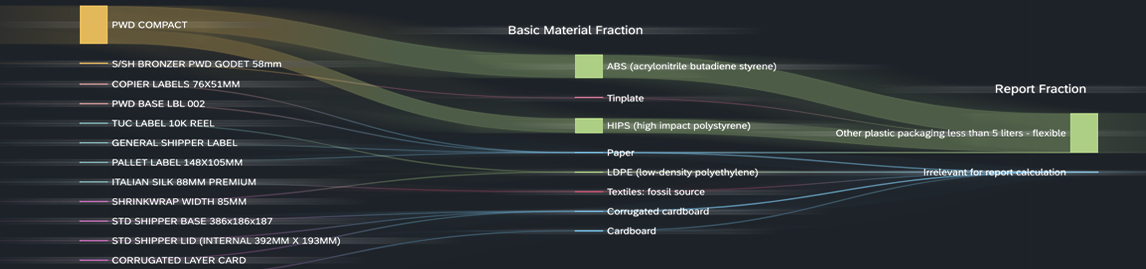

Sales documents provide information on the number of products sold in a specific geography and timeframe. The link from the product to its packaging allows reports to determine material categories and calculate weights and tax liabilities.

The data model has to link the sales volume with the material fraction and attributes.

The sustainability thread in action—this short demo of SAP Responsible Design and Production illustrates how a foundational, cross-system data model for packaging can drive dynamic reporting for EPR and plastic tax calculations.

Enabling Interoperability Across Systems

To realize the sustainability thread, organizations must identify which systems house the relevant data and ensure interoperability between them. Examples of system mappings include:

| Data Object | Possible Systems |

| Material Attributes | PLM, Supplier Portal, ERP, Excel |

| Packaging Element | PLM, Packaging Management, ERP |

| BOM (Packaging) | PLM, ERP |

| Product (SKU) | PLM, ERP |

| Sales Data | ERP, Logistics, Customer Management Systems |

Organizations can achieve interoperability by:

- Maintaining the model in one system with custom built-in reporting. (e.g., SAP PLM)

- Integrating multiple systems and reporting tools.

(e.g. Teamcenter, S/4, and PowerBI) - Implementing a central platform like SAP Responsible Design and Production (RDP) to pull data across systems.

Conclusion: From Compliance Burden to Strategic Advantage

As EPR regulations expand, businesses must act decisively to establish the infrastructure for consistent, accurate reporting. A robust sustainability thread offers the strategic foundation to navigate this evolving landscape.

Linx-AS can support organizations by:

- Analyzing reporting jurisdictions to identify required material data,

- Consulting to build a comprehensive data model,

- Assessing existing business systems to determine data reuse potential

- Developing a system and architecture roadmap for the sustainability thread

With the right expertise and a clear plan, companies can turn compliance from a burden into a competitive differentiator.